In an era where manufacturing precision meets global demand, Sunyung stands out as a beacon of innovation and reliability. With a 15,500㎡ state-of-the-art facility and a production network spanning 25 countries, we’ve built our reputation on three pillars: strict quality control, customer-oriented service and continuous new product development. Let’s take a deep dive into how our production process sets new-level standards.

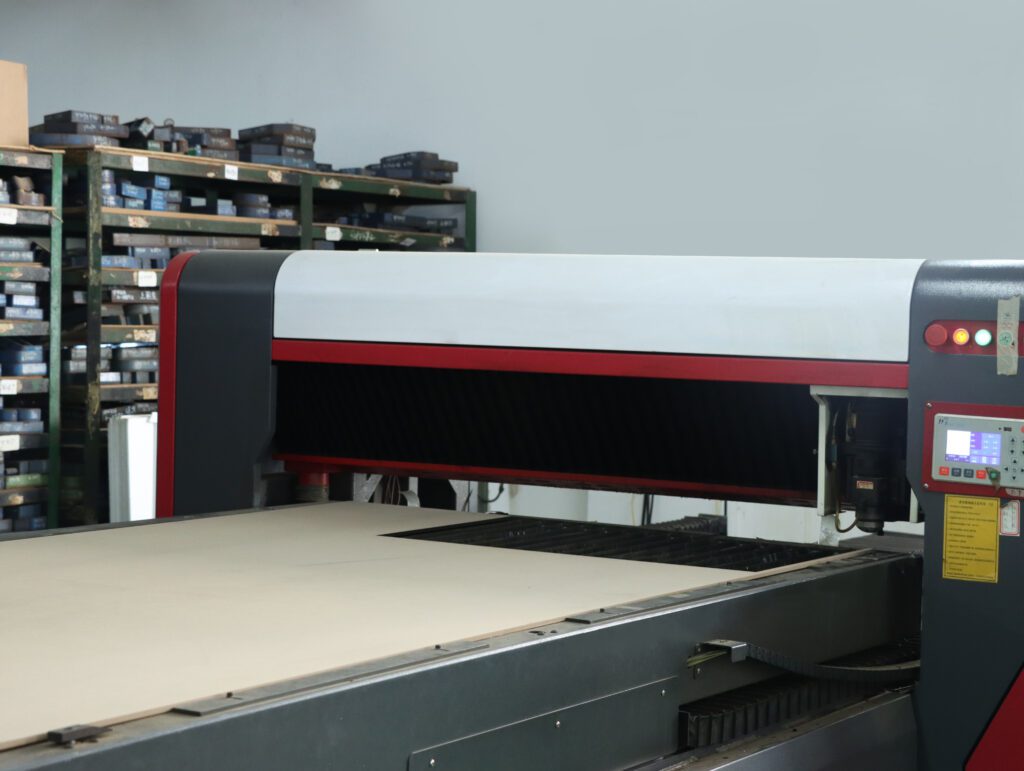

Advanced Automation: Where Technology Drives Efficiency

At Sunyung,automation isn’t just about speed—it’s about consistency and precision. Our production lines are equipped with the new machines and -driven controls, ensuring minimal human error and maximum output.

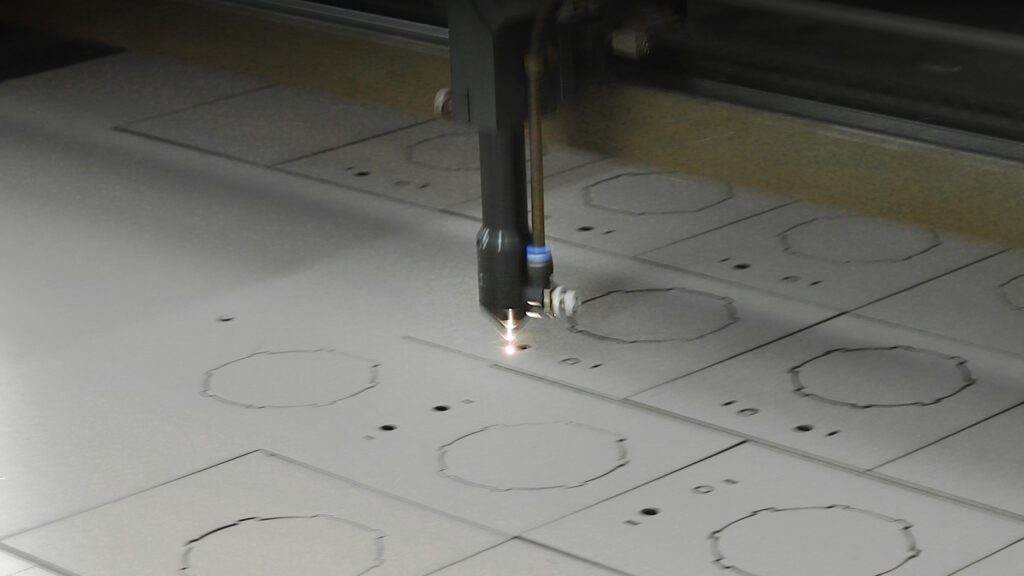

- Laser Machining: From high-speed assembly cutter to automated material handling systems, our equipment operates with millimeter-level accuracy. This technology reduces production time by 35% while maintaining a defect rate below 0.01%.

- Data-Driven Optimization: Real-time monitoring systems collect and analyze production data on production lines. This agility ensures we meet even the most stringent delivery deadlines.

Precision Control: The Art of Manufacturing Perfection

Our commitment to precision is evident in every component we produce. Sunyung’s precision control technology ensures that each product adheres to exact specifications, whether it’s a glue consumption or a large-scale material part.

Laser Machining: Our fleet of Laser Machining, calibrated to 0.1mm tolerance, delivers unparalleled accuracy.

Continuous Process Monitoring: Every stage of production is ensuring that deviations are detected and corrected in real time.

Quality Assurance: ISO 9001 Certified, Customer Approved

Quality isn’t just a goal at Sunyung—it’s a promise. Our ISO 9001:2015 certified quality management system covers every aspect of production, from raw material inspection to final product testing.

Rigorous Testing Protocols: Each product undergoes a battery of tests, including 100% of raw material, production, assemble, functional testing, endurance & reliability and environmental testing, final inspection before packing, and pre-shipment random sampling (AQL standard).

Skilled Quality Control Team: Our QA professionals, with an average of 8+ years of experience, conduct thorough inspections at every stage. This human-machine collaboration guarantees that only the highest quality products leave our facility.

Global Reach: Serving 25 Countries with Local Expertise

With customers in 25 countries across Europe, Asia, and the Americas, Sunyung understands the importance of global presence with local support. Our strategically located distribution centers ensure fast delivery, while our multilingual customer service team provides round-the-clock assistance.

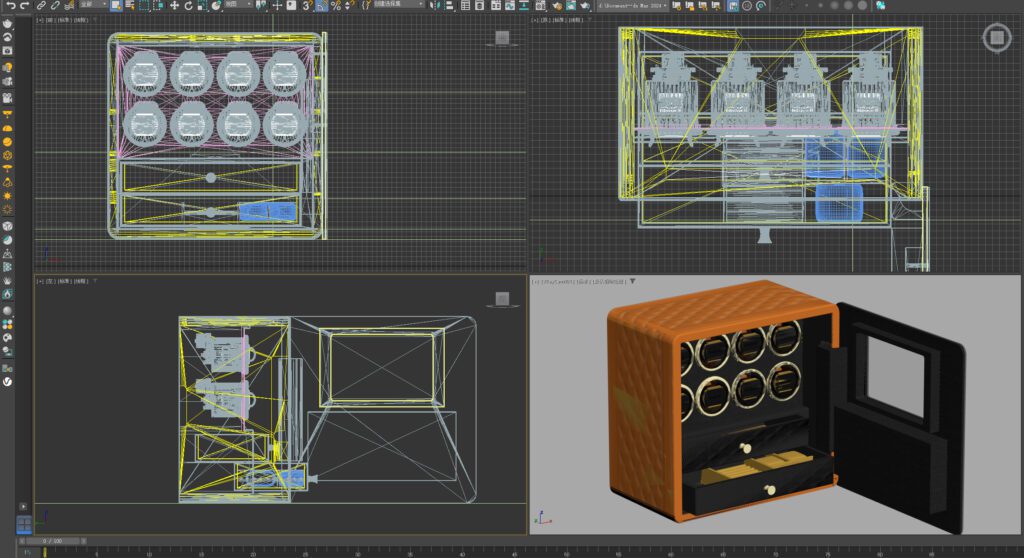

Tailored Solutions: We work closely with clients to develop customized production solutions that meet regional standards and market demands.

Sustainable Practices: As part of our commitment to the planet, we’ve invested in cnc machines and waste reduction programs, reducing our glue by 5%, wood materials by 20% and leather material by 10% in the last three years.

Join the Sunyung Network

Whether you’re a Fortune 500 company or a growing enterprise, Sunyung is your trusted partner for precision manufacturing. Let’s collaborate to bring your vision to life—with the quality, efficiency, and reliability that only decades of expertise can deliver.

Connect with us today to learn how we can elevate your production process.